British aircraft engine manufacturer Rolls-Royce has completed building its UltraFan technology demonstrator, paving the way for the first test to take place in early 2023.

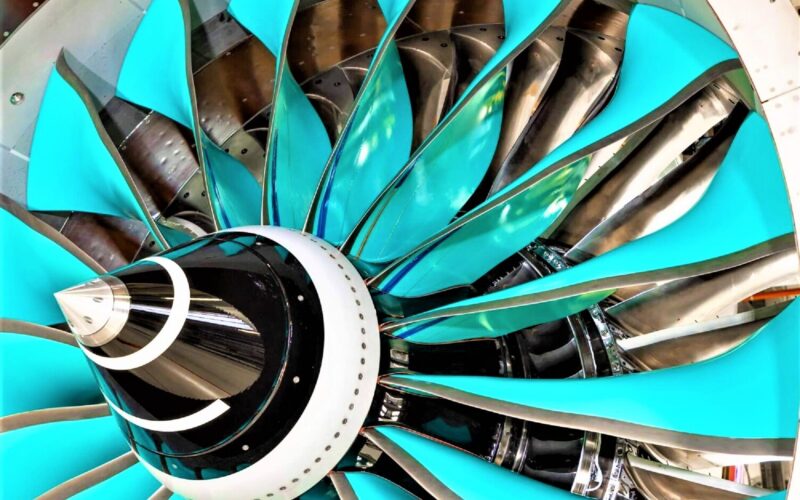

The plane engine maker announced that it has already moved the UltraFan demonstrator engine, which has a fan diameter of 140 inches (3.56 meters), into its Testbed 80 located in Derby, in the United Kingdom, where it was mounted for testing in the coming months.

“Seeing the UltraFan demonstrator come together and getting ready for test in Testbed 80 is a great way to end the year,” president of Rolls-Royce Civil Aerospace Chris Cholerton said.

“The next stage will be to see UltraFan run for the first time on 100% Sustainable Aviation Fuel [SAF, ed.-] in 2023, proving the technology is ready to support more sustainable flight in the future,” Cholerton added.

Featuring Advance3 core architecture and an ALECSys lean-burn combustion system, the new Rolls-Royce engine is estimated to offer a 25% fuel efficiency improvement compared with the first generation of the Trent engine. The new engine is also expected to feature a range of propulsion options, including current jet fuel, SAF, hybrid-electric, and hydrogen.

Rolls-Royce said it plans to transfer technologies from the UltraFan development program to existing Trent engines to make them more fuel efficient and to significantly cut engine emissions.

Meanwhile, the manufacturer estimates the UltraFan’s scalable technology can improve the fuel efficiency of both narrowbody and widebody planes by up to 10% in the long term.

The world’s largest aero-engine could enter the service with future narrow-body or widebody aircraft in the 2030s, the manufacturer said.

Currently, the largest commercial aircraft engine available in the market is the GE9X, which is made by the American manufacturer, General Electric.