After Virgin Australia pilots reported that their Boeing 737-800 tended to roll to the right after take-off, the Australian Transport Safety Bureau (ATSB) has recommended that operators should be more stringent when checking the aircraft’s wing flaps.

The incident occurred on April 27, 2022, when a Virgin Australia Boeing 737-800 Next Generation, registered as VH-YFZ, began to roll to the right immediately after take-off. The aircraft took off from Gold Coast Airport (OOL) and was scheduled to fly to Sydney Airport (SYD), where it successfully landed.

While the tendency to roll right was not present during the cruising phase of the flight, the issue returned when the flaps were once again extended, the ATSB noted in its report.

The jet was delivered new to Virgin Australia in September 2017, according to planespotters.net data. The Boeing 737-800 still belongs to Virgin Australia and has continued to fly passengers in Australia.

ATSB pointed out a worrying trend

Although not sighted in a previous visual inspection, several instances where cracks and failures occurred in the same part were spotted between 2017 and 2022. However, Boeing deemed that the issue does not warrant safety action, the report noted.

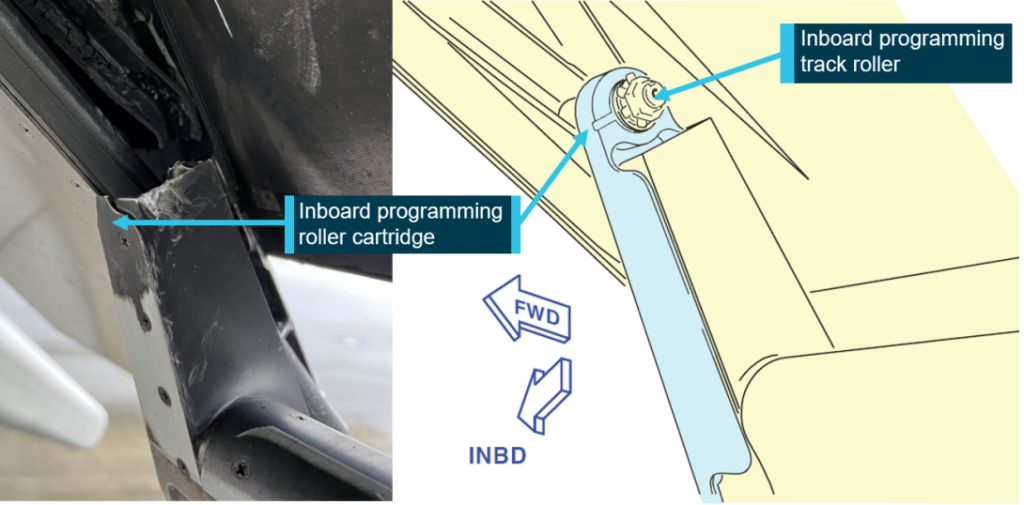

“A walk-around inspection after the flight found the outboard aft flap on the left wing had not completely retracted, and a subsequent inspection found several components in the aft flap actuation system had failed,” stated Angus Mitchell, the Chief Commissioner of the ATSB. Mitchell noted that the aft flap actuation system was last inspected in October 2020, when no defects were discovered.

“While it could not be determined whether the fatigue crack was present at that inspection, 10 other instances of cracking and/or failure of the programming roller were reported to Boeing between 2017 and 2022, and at least six of these were old enough to have been inspected several times prior to failure,” the chief commissioner added.

In this case, the ATSB indicated that the incident occurred “due to undetected fatigue cracking that occurred in an area that was not included in the detailed flap actuation system inspection”. It deemed it a safety issue, which can “reasonably be regarded as having the potential to adversely affect the safety of future operations”. Furthermore, the ATSB notes that a safety issue “is a characteristic of an organization or a system, rather than a characteristic of a specific individual, or characteristic of an operating environment at a specific point in time”.

However, the manufacturer of the aircraft responded that following an analysis of its Federal Aviation Administration (FAA)-approved risk management program, a “review of prior failures shows that airplane-level effects were correctly mitigated by flight crews and the affected aircraft landed without further incident”.

“Boeing’s review indicates that the event does not represent a significant reduction in airplane safety margins, and that the current inspection program is adequate”, the planemaker continued in its response to the ATSB.

The bureau, in its response to the Original Equipment Manufacturer (OEM), stated that while it does recognize that the planemaker’s risk management program does not deem this a safety issue, “the frequency of occurrence—particularly in the past 5 years— warrants safety improvement in the detection of fatigue cracking prior to failure”.

“The ATSB also notes that a detailed inspection of the flap actuation system already exists, and while it includes the aft flap rollers, it does not include the cartridges that house them. Inclusion of the cartridges in the detailed inspection would provide the greatest opportunity for fatigue cracks to be identified prior to failure,” the agency’s response to the manufacturer concluded.