For the aviation MRO industry adopting new practices and new technologies has always been high on the list of priorities; change has always been a constant. However, one of the major hurdles the MRO industry is facing at present is the impending headache of labor shortages and the procurement of highly skilled workers. Thankfully, there are solutions at hand.

One of the main reasons behind the lack of skilled workers is time-based. Suitably qualified aircraft maintenance technicians (AMT) can take up to eight years to reach the stage of becoming a fully-licensed AMT. This elongated time scale can significantly impact outdated line maintenance processes which give rise to overruns on MRO planning time and an upsurge in unplanned tasks.

While the aviation MRO industry may feel somewhat shackled by the lack of maintenance technicians, which in turn may lead to an increase in maintenance costs being incurred by airlines, the answer lies with enhanced optimization practices and the implementation of advanced software solutions.

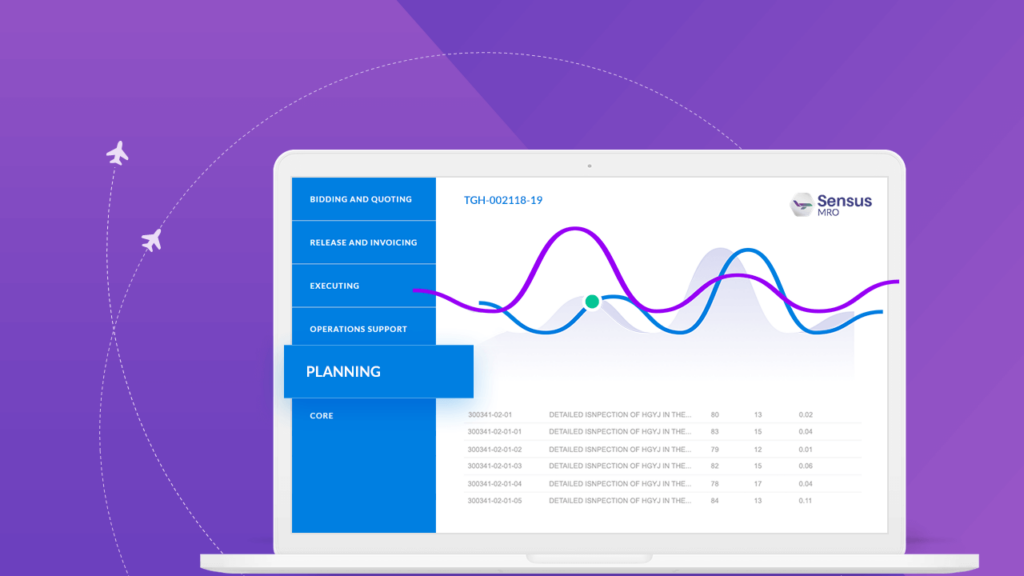

Despite the voids that may be created by increased labor shortages the introduction of process-sculpting modern solutions, like Sensus MRO, an advanced aviation ERP (Enterprise Resource Planning) tool, can help to fill that void and compensate for a wide range of factors affecting productivity.

Many areas of the old MRO process were liable to hemorrhage both time and money. However, with the implementation of modern MRO software, the industry will be better equipped to remedy the situation with the assistance of intelligently-driven resources designed to manage all aspects of MRO projects from beginning to end.

Sensus MRO can apply effective solutions in identifying and resolving gaps in real-time work scheduling, MRO time tracking, and visibility across an entire project. Despite labor shortages, the software can more than compensate through intuitive planning – eliminating wasted process time – monitoring and tracking metrics for simplified analysis by line managers and supervisors, resourceful work prioritization, and significantly increase the efficiency of inventory tracking and material planning.

The aviation MRO industry has always been about attention to detail. Sensus advanced MRO software allows these details to be minutely analyzed and returned in an easily understandable format as exact data and actionable metrics. This comes as a win for both MRO companies and the airlines they service. MRO managers are given the ability to track time spent in both productive and non-productive tasks, which can, in turn, lead to the redeployment of workers to more productive tasks, reducing billable costs, and reducing turn-around times – exactly what the airlines demand.

It is these visible benefits in terms of time and savings, that draw major airlines – in search of pain-point solutions for their fleet maintenance – to trusted and forward-thinking MRO suppliers. With a significant swing towards outsourcing line maintenance, repair, and overhaul to specialist MRO providers, every tool that can provide leverage should be embraced with open arms. Plus, as the airline and aerospace industry has changed so much in recent years the larger airlines are taking full advantage of every new development, Artificial Intelligence (AI), the Internet of Things (IoT), and Big Data. These changes are forcing airlines and their partners, to address the implementation of optimization software to decrease aircraft-on-ground (AOG) times and reduce maintenance spend.

While the problem of labor shortage still exists – Boeing has estimated that the airline industry will need approximately 600,000 AMTs over the next 20 years – its impact can be measurably lessened with the onboarding or upgrading of optimization software tools like Sensus MRO.

The airline industry is forever looking to the future. It is and always has been new challenges, just like the present AMT labor shortage, which drives it ever forward, and in doing so, demands higher standards, keener cost-cutting, more sustainability, and improved practices for streamlining operations across every sector.

Being first off the blocks to adopt new practices and new technologies has always been a prerequisite of the industry, and it always will be.