Used to describe the central body of a flying machine, the word ‘fuselage’ originated in France in the early 1900s. It comes from the French word ‘fuseau’, meaning ‘spindle’, and refers to the shape of the body.

The fuselage is a key component of an airplane, housing the crew, passengers, and cargo, and providing structural support for the wings and tail. There are several types of fuselage design, each with its own strengths and weaknesses, which are carefully considered by aircraft designers.

Different types of fuselage

Truss

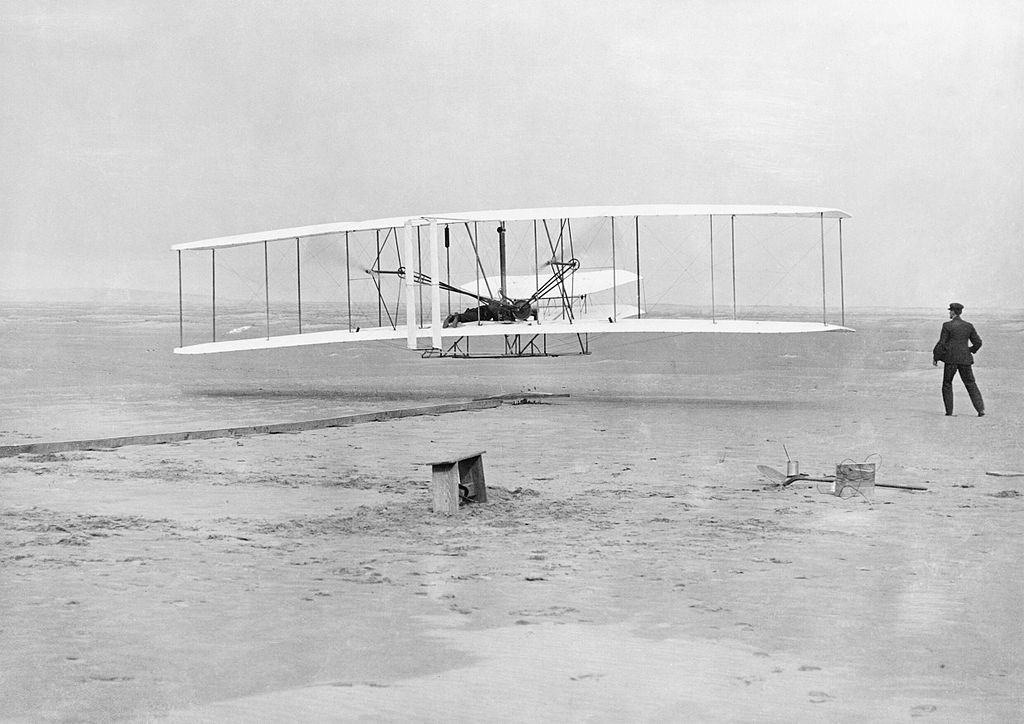

One of the earliest types of fuselage design is the truss, which is made up of a framework of interconnected metal or wooden beams. This kind of fuselage is relatively simple and easy to construct. It was commonly used in early aircraft days for airplanes such as Wright Flyer and Douglas DC-3. However, it is not as aerodynamically efficient as other designs and can be heavy, which contributes to various issues such as higher fuel consumption, increased noise pollution, infrastructure limitations, accelerated runway wear and tear and limited destination access, plus negative environmental impacts including higher carbon emissions.

Geodesic

Another type of truss fuselage is the geodesic variety, which uses a lattice of interconnected triangular or hexagonal sections to provide strength and rigidity. This type of fuselage was popularized by aircraft designer R.J. Mitchell, who deployed it in the famous Supermarine Spitfire fighter plane of World War II.

Monocoque

A common fuselage type in modern aircraft is the monocoque. Monocoque means ‘single shell’ in French, and this fuselage is constructed as a single unit, with the skin of the aircraft providing structural support. This design is more aerodynamically efficient and lighter than truss structures, though it requires more advanced manufacturing techniques. Examples of aircraft that use monocoque structures include the de Havilland DH.88 Comet, the Airbus A380, and the Boeing 787 Dreamliner.

Semi-monocoque

The semi-monocoque structure consists of a series of stringers (longitudinal structural members that run parallel to the aircraft’s longitudinal axis) and longerons (longitudinal structural members that run along the fuselage’s longer axis) that run longitudinally along the length of the fuselage, with thin sheets of aluminum or composite materials covering the framework to provide the necessary strength and stiffness.

This type of construction is commonly used in commercial airliners, business jets, and military aircraft due to its strength, lightweight, and durability. Examples of aircraft built using semi-monocoque structures include the Airbus A350 and the F-22 Raptor fighter jet.

The importance of fuselage types in aircraft design

Different types of fuselages tend to be used in small and large aircraft. Generally, smaller aircraft tend to use simpler fuselage designs, such as truss or semi-monocoque structures, due to their lower weight and simpler manufacturing requirements. Larger aircraft typically use more complex and advanced monocoque or composite structures, which offer greater strength and durability while also minimizing weight.

Jet fuselages are designed specifically for high-speed flight and make use of a streamlined shape to reduce drag. They are typically made of lightweight materials such as aluminum or composite materials, which offer a high strength-to-weight ratio.

In addition to the basic design of the fuselage, there are also variations in the shape and configuration of the fuselage based on the intended use of the aircraft. For example, commercial airliners typically have a cylindrical fuselage with a large passenger cabin, while military aircraft may favor a more streamlined or angular shape to improve their speed, maneuverability, or passive stealth characteristics.

Recent advances in composite materials have enabled designers to create even lighter and stronger fuselages, which can improve fuel efficiency and increase payload capacity. Additionally, 3D printing technology has made it possible to create complex and intricate shapes that were previously difficult, or even impossible, to produce using traditional manufacturing methods.

Overall, the type of fuselage used in an aircraft is an important consideration for designers as it affects the aircraft’s performance, weight and safety. By carefully selecting the appropriate fuselage design, aircraft designers can create efficient and effective aircraft that meet the needs of their intended purpose.

Learn more about aircraft fuselage design: