The French General Directorate of Armaments (DGA) completed a first test for the development of the engine that will power the Future Combat Air System aircraft.

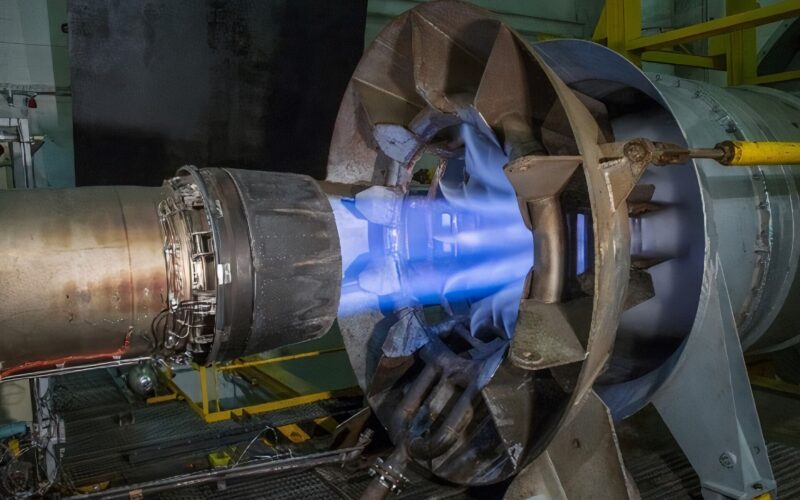

The DGA announced on January 10, 2021, that a prototype derived from the M88, the engine of the Dassault Rafale fighter, was trialed on a test bench as part of the Turenne defense technology project.

“This test is distinctive by the technique used, called Thermocolor, which requires heat-sensitive paint; applied to the blades of the engine’s high-pressure turbine blades, it measures the temperature thanks to a color change,” the DGA explained. “This type of trial is very rare; the most recent at DGA Propellant Testing dates back to 2010.”

It took five years for the conditions to be ready for this experiment. Once the results of this first test are analyzed, the project will move on towards an “endurance” test that should last several months.

“Each of these advancements is a unique and necessary piece of a puzzle of technological innovation. Combined with a latest-generation engine, they will make it possible to achieve the level of performance expected from the SCAF program,” the DGA concluded.

According to the French Ministry of Armed Forces, the New Generation Fighter (NGF) sixth-generation fighter jet developed by France, Germany, and Spain in the framework of the Future Combat Air System (FCAS) will require more powerful engines than its predecessors.

Higher thrust means higher temperatures. The conditions could reach 2100 Kelvin (1826.85 degrees Celsius) at the turbine inlet – 250 Kelvin (250 degrees Celsius) more than those of the M88. Current materials are not able to sustain such conditions.

Consequently, the DGA along with the French national aerospace research center (ONERA), and the engine manufacturer Safran were contracted by the Ministry to accelerate the development of “new metal alloys and multilayer systems for high-temperature applications on turbine blades and disks”.